Leister recommends closed-loop technology for more welding reliability on the roof

Using the new VARIMAT V2, polymer roofing membranes can be welded more rapidly resulting in lower cost. Users appreciate its streamlined ergonomics and its ease of use. The clearly laid out operating unit‘s „e-drive“ allows for the control of all relevant welding parameters.

Welding of modified bitumen sheeting (SBS, APP) with the flameless BITUMAT B2 is much safer than welding with an open flame. The weld strength is significantly better and the single step process makes welding more economical.

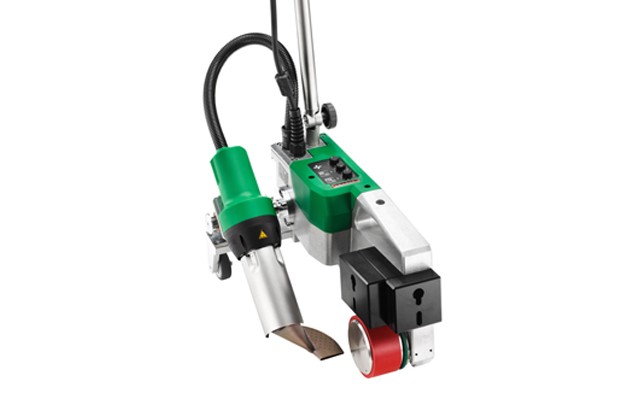

The unique, semiautomatic welding tool. The flexible concept makes the TRIAC DRIVE AT an all-around tool that is universal in use.

The unique, semiautomatic welding tool. The flexible concept makes the TRIAC DRIVE AT an all-around tool that is universal in use.

The new UNIROOF AT/ST roof welder is your flexible partner for welding thermoplastic roofing membranes on flat or pitched roofs (up to 30°). Thanks to its slim design and construction, as well as the movable transport axle (patent pending), converting of the machine is no longer needed. Now, you can effortlessly weld close to the edge (to 100 mm ) at the parapet or on the parapet and as easily in narrow circumstances.

For specific material like EPDM/modified bitumen (e.gResitrix) and also TPO/PVC membrane

Copyright © 2023 GLOBAL SOURCE. All Rights Reserved. Designed by TEAM GLOBAL